|

Optical Lens

|

LED Lens

LED by LDE lens of secondary light-gathering helped to raise the LED out light efficiency, change the LED light field distribution of optical system.

1.Silicone lens

A. because of silica gel and heat-resistant high (can also lead reflow), so

commonly used in LED directly encapsulation chip.

B. general silicone lens smaller, 3-10mm

diameter.

2. PMMA lens

A. optical PMMA (poly methyl methacrylate, commonly known as: yakeli).

B. plastic materials, advantage: high production efficiency (by injection,

extrusion finish); Light transmittance high (3mm thickness transmittance 93% controlled); Faults:

temperature cannot exceed 80 ° (heat distortion temperature 92 degrees).

3.PC lens

A. optical materials Polycarbonate (hereinafter referred to as PC)

Polycarbonate.

B. plastic materials, advantage: high production efficiency (by injection,

extrusion finish); Light transmittance slightly low (3mm thickness transmittance 89% controlled); Faults:

temperature cannot exceed 110 ° (heat distortion temperature 135

degrees).

4.Glass lenses

Optical glass material, and advantages: it features light transmittance high (3mm thickness transmittance 97%),

temperature higher characteristic, Faults: big volume quality heavy, shape

single, fragile, batch production not easy to attain, production efficiency is

low, the cost is high.

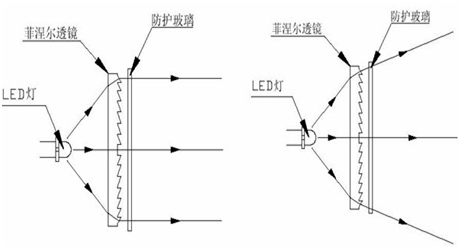

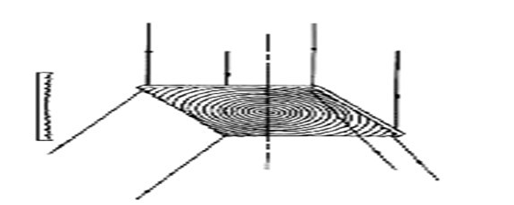

Card Magnifier

The Fresnel magnifying glass, this is a ultra-thin a magnifying glass.

With transparent organic glass (of course, also can use more materials) is

made. Use PVC made of Fresnel a magnifying glass, the smallest thickness can be

in 0.45 mm ~ 0.90 mm between, general with the

magnifying glass is different, its surface was full of tiny stripe, in its

spiral shape stripe contains many convex (hereinafter referred to as round

ring), make through its light bending arise namely diffraction phenomena

(diffraction phenomenon is light volatility characteristics. The Fresnel

kingdom physicists to diffraction theory made outstanding contribution.

Therefore the Fresnel also by his name come), thus forming amplification of the

image. The Fresnel lens is characteristic of than normal lens high brightness

and the surface smooth, radiating surface area is big also. Ordinary convex

lenses its diameter is limited, while the Fresnel the magnifying glass in this

field plays a very good effect, achieve the common lens can not achieve the

effect. And now make the Fresnel magnifying glass ply has 0.45 mm, will carry, in fact the main role is to reduce

the traditional magnifying glass creates the ordinary organic glass, a

magnifying glass the weight and volume.

PIR Reflecting Mirror

Due to the limitation of the Fresnel lens single sensor for customers, our company specially for the reflection infrared radiation of inductive lens, used to increase the heat release inductive sensitivity and Angle. It is the use of infrared light reflex law principle of work, wide Angle heat release infrared light through the Fresnel lens refraction, some will reach heat release infrared sensor center trigger sensors to work, another part of light will touch smooth reflecting surface again reflect or diffraction to mirror reflection, again reflection to the sensor center trigger work and thus compensated the single sensor Angle and sensitivity of weakness.

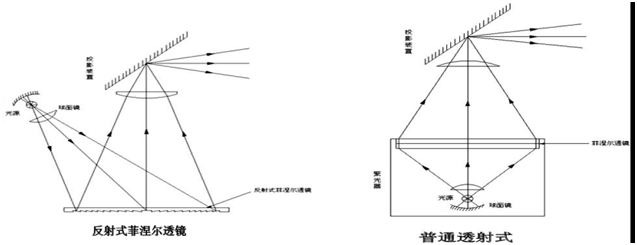

Now the extensive use of overhead projector, also called writing projection device, and its structure, principle and transmission type epidiascope similar, but the two flat for spotlighting with two threads are convex lens substitute. Because of the big picture will it slides, need of large size of convex for condenser, and large diameter of convex very heavy, very thick, use rise very inconvenient. People have developed a can make the very thin large diameter convex. This is threaded lens. Thread lens is similar to a convex, focusing on one hand gather light imaging; on the other hand, make the light even irradiate overhead. Its role with the original flat convex is same, but light.

Threaded lens and flat convex compared with thickness thin, light weight, good pervious to light, easy processing, etc. It is general by polypropylene suppression and become, threaded lens identifiable by surface formation. The screw lens is suppressed by poly propylene within and become, at higher temperatures than 70. C which will happen deformation, therefore, in light and threaded lens can add put a piece of new between YueJing.

|

|